Supporting the U.S. Air Force and Barksdale Air Force Base through technology—

LSU Shreveport’s Cyber Collaboratory Sparks Innovation and Military “Change in Mindset”

Through sustained collaboration with STRIKEWERX, the innovation hub of the U.S. Air Force Global Strike Command, LSU Shreveport’s Cyber Collaboratory has become a key provider of expertise and innovative solutions for nearby Barksdale Air Force Base and the nation’s air defense.

“We could have built our own maker space, but instead, we chose to collaborate with LSUS,” said Russ Mathers, director of STRIKEWERX. “From hardware, advanced modeling, and 3D printing to software and simulation, the Cyber Collaboratory has great capabilities, and we love to get them involved in projects that benefit our Airmen and, ultimately, our national security.”

STRIKEWERX frequently organizes what they call “design sprints” to help solve problems for the U.S. Air Force in five days or less. LSUS is always invited. Recent projects include maintenance of the now 60-year-old B-52 Stratofortress bomber planes, several of which are stationed at Barksdale, as well as maintenance of the 450 underground silos that are the launch facilities for the nation’s intercontinental ballistic missiles, or ICBMs.

Several recent LSUS-STRIKEWERX collaborations concern maintenance and training for B-52 bombers, several of which are stationed at Barksdale Air Force Base in Shreveport.

“Instead of buying our own equipment, maintaining it, and keeping people trained to use it to help solve some of these critical challenges, it’s better for us to go to the people who are experts and partner with them,” Mathers said. “Working with the LSUS Cyber Collaboratory has paid huge dividends for us.”

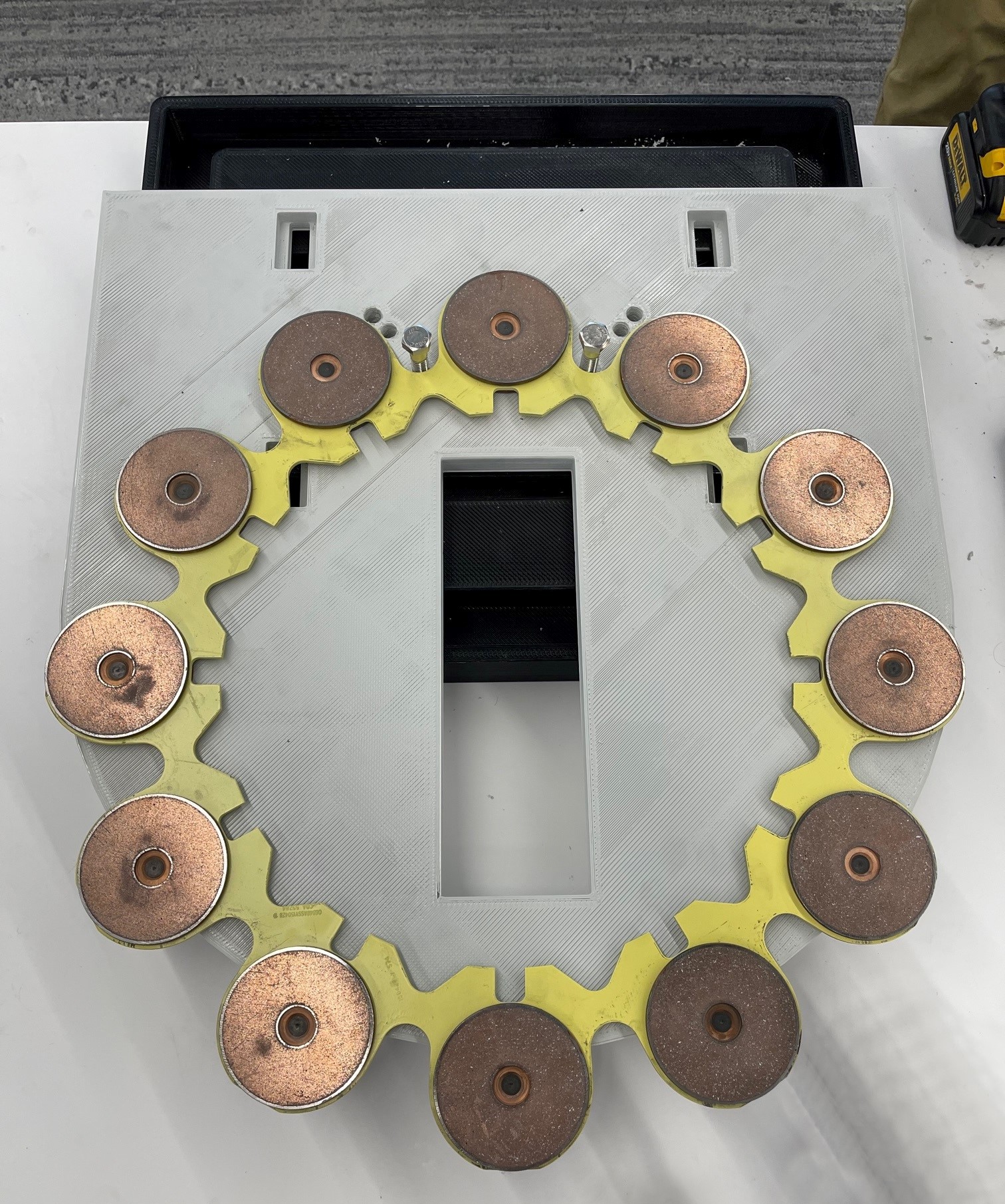

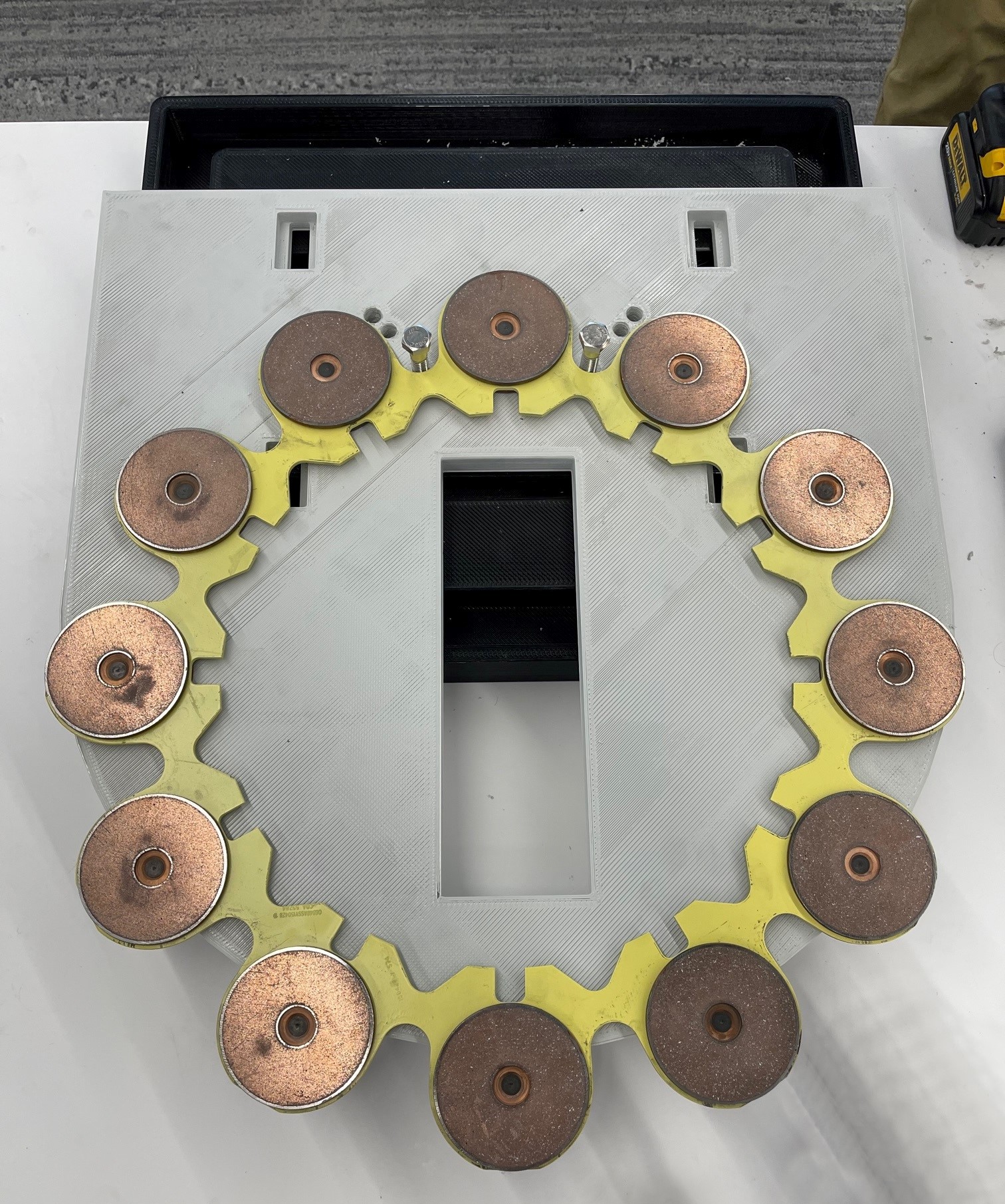

When the B-52 was first introduced, it was America’s hallmark heavy bomber. It began as an intercontinental, high-altitude nuclear carrier during the Cold War, and was later modified for low-level flight, conventional bombing, and transport. The B-52s in use today were all built between 1961 and 1963 and are mainly housed at either Barksdale Air Force Base in Louisiana or Minot Air Force Base in North Dakota. They’re expected to remain in service until 2050, but maintenance can be a challenge. For example, it takes a lot of power to stop an eight-engine, 488,000-pound jet loaded with weapons and equipment, and Barksdale Airmen were spending significant time drilling out carbon fiber brake pads for every B-52 in the country. As they were doing it manually and by eye, it was a difficult and even “dreaded” job, according to Mathers.

“They would often miss the exact center and have to start over, which wasted a lot of time and materials,” Mathers said. “To solve this, LSUS designed and 3D-printed a custom jig to hold and center the brake pads for drilling. LSUS took a 16-hour job and turned it into a two-hour job, saving $106,000 in materials and $18,000 in time per year.”

By designing a custom jig for drilling brake pads for B-52 bombers, the Cyber Collaboratory is saving the Air Force and Barksdale Air Force Base $106,000 in materials and $18,000 in work hours each year.

Because of their successful collaboration with Barksdale Air Force Base, LSUS recently helped take home the Air Force Global Strike Command’s Doolittle Award for Innovation Excellence for most innovative team. It’s a competition among eight bases across the nation.

Another recent STRIKEWERX design sprint led to LSUS coming up with a pre-filtration system for air intakes at ICBM launch sites. Generally located in the middle of farmland and up to three hours away from military bases, each underground silo hosts computers and avionics that depend on cool and clean air, and Air Force maintainers were spending a lot of time making unplanned trips to clean chaff and debris off cooling coils, especially during harvest season.

“With a three-hour drive to the site with the alarm, time to do the cleaning, and three hours to return back to base, these unplanned trips, which you also have to make within 72 hours, pretty much shot maintainers entire days and made it very difficult to do scheduled work,” Mathers said.

For example, Francis E. Warren Air Force Base in Wyoming and Malmstrom Air Force Base in Montana had to send Airmen out for 499 unscheduled cleanings between 2018 and 2020.

“Partnering with LSUS gives us a different perspective on how to tackle problems,” said Master Sergeant Edward Burlison with the Air Force Global Strike Command Logistics Directorate’s maintenance division and innovation branch. “As a missile maintainer, I see the same problems day in and day out, and I get used to looking at them in a certain way. Working with LSUS students and experts is an opportunity to get beyond that narrow focus and become aware of new technology and methods.”

Each of the LSUS-STRIKEWERX engagements also involve students who gain experience solving real-world problems. Beyond the design sprints, the partners organize trainings. They’re about to host the third cohort of Striker Airmen Coders, a program that brings together Airmen, students, and industry (in this case, Ruby Shore Software in Shreveport) to help the Air Force solve problems in the cyber sphere.

Taylor Bornman is an LSUS computer science student who participated in the first Striker Airmen Coders cohort. She helped an Airman develop a dashboard to monitor the always changing statuses of different Airmen. Throughout, she received technical guidance from Ruby Shore.

LSUS computer science senior Taylor Bornman (on right, with her son on her right) was among the first to participate in Striker Airmen Coders, a program that brings together Airmen, students, and industry (in this case, Ruby Shore Software in Shreveport) to help the Air Force solve problems in the cyber sphere.

“It was a great experience,” Bornman said. “As a junior, I had mostly done back-end programming, so this was an opportunity to focus more on the user interface. I was happy to gain the experience since I also worked fulltime for the Shreveport Police Department doing fingerprint matching and was unable to seek internship opportunities outside the local area.”

Bornman will graduate from LSUS with a bachelor’s degree in computer science this May.

Another recent training brought Airmen from three bases, including Barksdale, into the LSUS Cyber Collaboratory. As the military is investing in their own 3D-printing equipment for rapid prototyping, personnel also need to learn how to use it effectively.

A recent Cyber Collaboratory class on additive manufacturing and 3D printing brought Airmen from three bases, including Barksdale, onto the LSUS campus. As the military is investing in their own 3D-printing equipment for rapid prototyping, personnel also need to learn how to use it effectively.

A recent Cyber Collaboratory class on additive manufacturing and 3D printing brought Airmen from three bases, including Barksdale, onto the LSUS campus. As the military is investing in their own 3D-printing equipment for rapid prototyping, personnel also need to learn how to use it effectively.

Technical Sergeant Brandon Eastman with the U.S. Air Force’s Air Education and Training Command attended the recent additive manufacturing and 3D printing course at LSUS.

“By using the LSUS Cyber Collaboratory as a way for us to learn about the new tools and technologies involved in 3D printing, we can now develop our own lesson plans and standardize them across the Air Force to help us solve problems,” Eastman said. “Anyone can purchase this kind of equipment, but without training, it tends to sit and collect dust. Meanwhile, we need solutions to specific challenges, such as creating new components for older aircraft to make them serviceable—not just at Barksdale, but world-wide.”

“A lot of this can be solved in the 3D printing and scanning space, and thanks to LSUS, we’re becoming multi-capable,” Eastman continued. “We can start trying new things, and whenever we have a question or run into a problem, we can simply pick up the phone. For us, it’s a change in mindset.”

Master Sergeant Dennis Zanoni with Air Force Global Strike Command at Barksdale Air Force Base participated in the same training.

“The LSUS 3D-printing course will have a huge impact on the entire Air Force,” Zanoni said. “We’re going to use it to build and standardize our own basic course, so others across the Air Force can learn and teach it. This makes it a force multiplier.”

Master Sergeant Dennis Zanoni, Air Force Global Strike Command, Barksdale Air Force Base

Master Sergeant Dennis Zanoni, Air Force Global Strike Command, Barksdale Air Force Base

LSUS also recently teamed up with Lumen Technologies in Monroe, Louisiana (formerly CenturyLink) and was selected as one of five finalists among 103 submissions in a STRIKEWERX challenge to build an augmented reality simulator to help B-52 pilots learn how to air refuel behind a KC-135 Stratotanker. While not selected to build a prototype, due to limited Air Force funding, LSUS continues to prove the vast capabilities of the university.

“All of these projects have been a great experience for us and for our students,” said Scott Isaacs, director of the LSUS Cyber Collaboratory. “I’m quite proud that we’ve been able to win several of these challenges and even beat out some very large aeronautics companies in rapid prototyping and design. It’s a testament to the innovation capacity we’re building here in Shreveport.”

Read more:

LSU Shreveport Cyber Collaboratory Develops High-Tech Tools and Talent in Northwest Louisiana, Finds New Partners

LSUS Boosts Biotech Innovation for Health in Northwest Louisiana

Contacts:

Elsa Hahne, LSU Office of Research & Economic Development, ehahne@lsu.edu

Erin Smith, Director of Digital Media & Website Management, erin.smith@lsus.edu

A recent Cyber Collaboratory class on additive manufacturing and 3D printing brought Airmen from three bases, including Barksdale, onto the LSUS campus. As the military is investing in their own 3D-printing equipment for rapid prototyping, personnel also need to learn how to use it effectively.

A recent Cyber Collaboratory class on additive manufacturing and 3D printing brought Airmen from three bases, including Barksdale, onto the LSUS campus. As the military is investing in their own 3D-printing equipment for rapid prototyping, personnel also need to learn how to use it effectively. Master Sergeant Dennis Zanoni, Air Force Global Strike Command, Barksdale Air Force Base

Master Sergeant Dennis Zanoni, Air Force Global Strike Command, Barksdale Air Force Base